The PCBs are the core of modern electronic devices. Depending on their applications in the end products, different materials are used. They can be Aluminum, Rogers, copper, metal, HDI, FR-4, among which FR-4 is the most common material used for PCB manufacturing today.

What is FR-4?

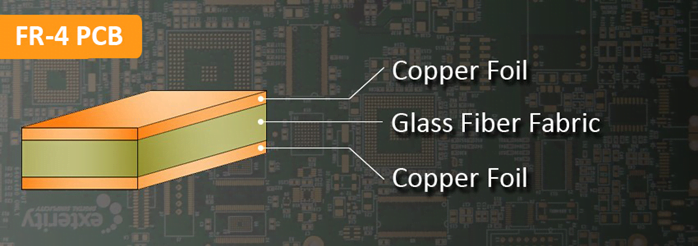

FR-4 is a class of glass fiber epoxy laminate. The FR in the term FR4 stands for flame retardant, which means that the FR-4 board will not sustain a fire. And the number 4 distinguishes itself from other materials in the same category. The term FR-4 also represents the grade used to make these laminates. The composition of the material is compliant with the standard UL94V-0. In single or double-layer PCB, an FR-4 board functions as an electrical insulator between two layers of copper foil in the top and bottom, while additional prepreg layers are laminated between the center core and top and bottom copper layers for multi-layer PCB.

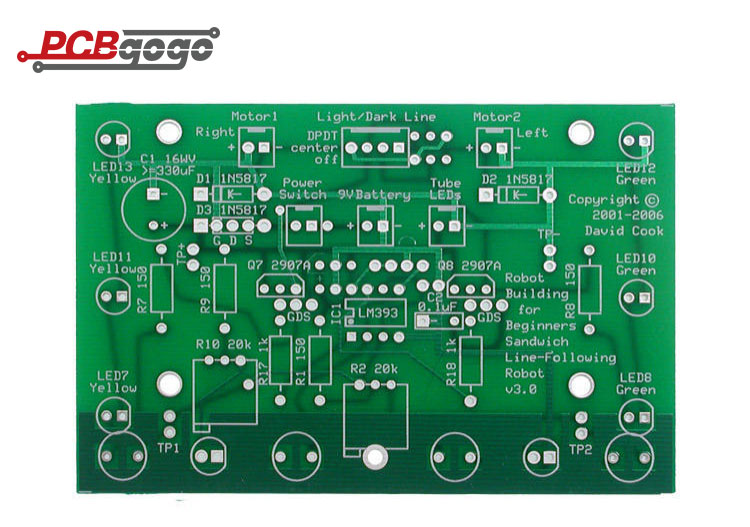

Figure 1 FR-4 PCB

Advantages of FR-4 PCB

FR-4 material is popular due to the following features.

FR4 is relatively low cost and affordable compared to other base materials while remaining effective for multiple applications.

It has high dielectric strength, that’s why it functions well as an electrical insulator and processes considerable mechanical strength.

It has a high strength-to-weight ratio and is light in weight.

It possesses outstanding electrical loss performance.

With near-zero water absorption, FR-4 PCB can perform well in humid conditions such as in marine applications.

The glass transition temperature(TG) of standard FR4 is between 130 – 140°C. Higher TG is greater than 170°C which offers a better mechanical and chemical resistance to heat and moisture.

Select the right FR-4 thickness for your PCB

When selecting the FR-4 for your project, you also need to specify the thickness. The FR-4 thickness might not be a significant aspect of the design but it has a certain impact on the functionality of the board. Following are some considerations you need to keep in mind.

Space

Thinner boards take less space. For small applications such as USB connectors and Bluetooth devices, a thinner FR-board is always preferable in a limited space. Thin FR-4 boards are also ideal in the case where space-saving is a concern for large devices.

Design

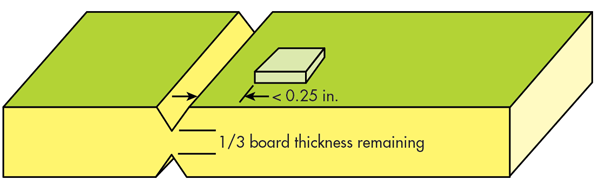

Thinner material is also not suitable for PCB with V-grooves as it would lead to a higher risk of board damage or fracture.

Figure 2 PCB with V-groove

Flexibility

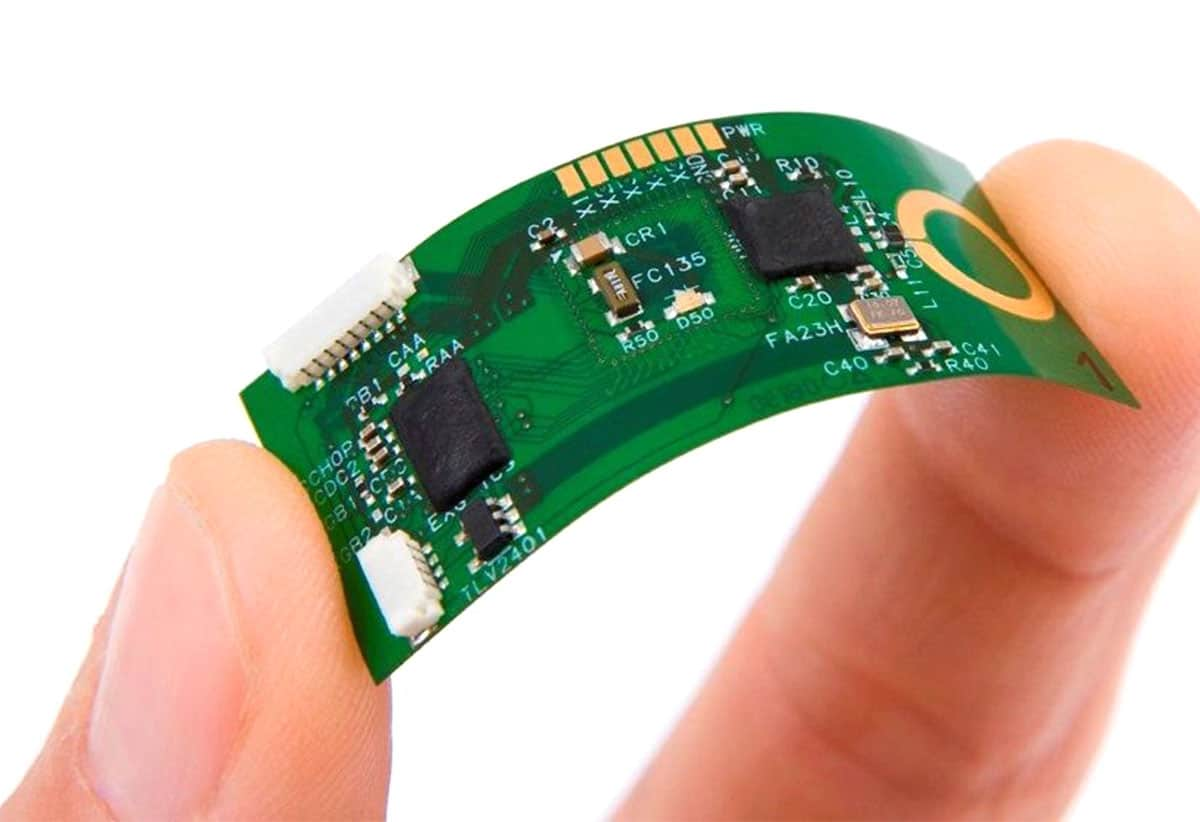

A thinner circuit board is bendable and can be applied to flexible devices. However, it may not be correctly assembled as some issues occur when it is put on the Pick&Place machine due to its flexible characteristic. Electrical connections of flexible PCBs are also more likely to be broken unless they are supported by some mechanical structure.

Figure 3 Bendable FR-4 PCB

Impedance matching

Every two or more layers of boards act as capacitors between traces on the adjacent layers. The thickness of the board determines the thickness of the dielectric and thus the value of the capacitance. For high-frequency signals where impedance matching is critical, capacitance is a key consideration when selecting the appropriate circuit board thickness for your design.

Compatibility with components

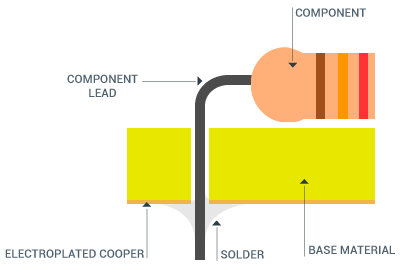

Some components especially through-hole devices are designed for thinner circuit boards. Selecting the right FR-4 board can be a determining criterion to be taken into account if your PCB requires components with a certain board thickness.

Figure 4 Through-hole component

Limitations of FR-4 PCB

The advantages of the FR-4 board make it an ideal solution for a wide range of electronics applications. However, it is not the answer for every design.

Insulating stability

A drawback of FR-4 is that it has operating limits when the power, voltage, or heat is too high. As mentioned above, FR-4 acts as an electrical insulator between the copper layers. If it exceeds its operating limit, the dielectric properties of FR-4 will be destroyed, meaning its insulation decreases, and it will begin to conduct electricity instead. Therefore, if your projects are developed for a high-temperature environment such as for aerospace applications, an FR-4 PCB is not an ideal choice.

Impedance stability

Another limitation of FR-4 is that it fails to keep a stable impedance for high-frequency design. That’s because the dielectric constant (DK) of FR-4 varies across the length and width of the board and also as the temperature change, which has a certain effect on the signal integrity.

Below is a comparison of FR-4 with other common PCB materials in terms of dielectric constant (DK).

|

PCB Material Comparison |

||

|

Base material |

DK(at 1MHz) |

Recommended Board types |

|

FR-4 |

4.2-4.8 |

Standard |

|

High TG FR-4 |

4.5-5.4 |

High Density |

|

CEM-1 |

4.2 |

High Density |

|

CEM-3 |

5.0 |

High Density |

|

Teflon |

2.5-2.8 |

High Frequency, Microwave,High Power |

|

PTFE |

2.1 |

High Frequency, Microwave,High Power |

|

Polyimide |

3.8 |

High Frequency, Microwave,High Power |

Signal loss

In addition to unstable insulation and impedance, FR-4 has a high dissipation factor (Df) that increases as the frequency increases. The higher the Df, the more is the overall signal loss. For non-high-frequency situations, a certain signal loss is acceptable, while in high-frequency design, it becomes an identical problem. In the case that signal loss is critical to your design, high-frequency laminate would be more suitable than FR-4.

Conclusion

Although FR-4 material has some drawbacks, it keeps a widely effective balance between cost, durability, performance, manufacturability, as well as electrical properties and thus becomes the most common and popular base material for PCB prototyping.

If you are looking for an FR-4 PCB manufacturer, look no further than PCBGOGO. PCBGOGO is a professional PCB prototype and PCB assembly manufacturer with over 10 years of experience. As we all know, the higher the TG of FR-4, the better its thermal reliability, especially in a lead-free process. By default, PCBGOGO offers standard FR-4 boards at TG 150 without extra costs. All of their materials undergo strict warehousing inspection and are provided with complete substrate material testing reports.

Figure 5 Fr-4 PCB manufactured by pcbgogo.com

To support more creative electronic engineers, PCBGOGO is now offering free trial orders for all users, which means everyone can enjoy free PCB prototyping once on their website. If you have ongoing PCB projects, don’t miss out! Check here for more details: https://www.pcbgogo.com/free-pcb-prptotype.html

- Comments(6)

P****yly

May 20.2024, 15:56:08

R****ner

Apr 23.2024, 11:45:34

b****kay

Dec 01.2023, 10:26:59

w****own

Nov 06.2023, 10:11:33

w****own

Nov 06.2023, 10:10:19

| [http://www.edgewall.com Key1] |

| [[http://www.edgewall.com|Key2]] |

| run 3:https://domain |

| [foo4]: http://example.com |

| <a href="https://domain">key5</a> |

| [url=https://domain]key6[/url] |

| run 3:https://domain |

| "shell shockers":https://shell-shockers.co |

w****own

Nov 06.2023, 10:09:16