Functional testing is the final step of the PCB assembly process. The PCB is tested to verify whether it functions correctly. The main purpose of the functional testing is to make sure the final PCB has no defects and meets specifications, which basically gives a pass or fail verdict on the PCB. In the functional testing, the PCB’s final electrical environment is stimulated. The behavior and functionality of various components are tested and verified under its intended working environment.

In this article, we will look at various aspects of PCB assembly functional testing. Some of the areas we will explore are the benefits of functional testing, areas examined in functional testing, functional testing plan, how to do functional testing, test fixtures and factors to consider when choosing a manufacturer for your PCB assembly test.

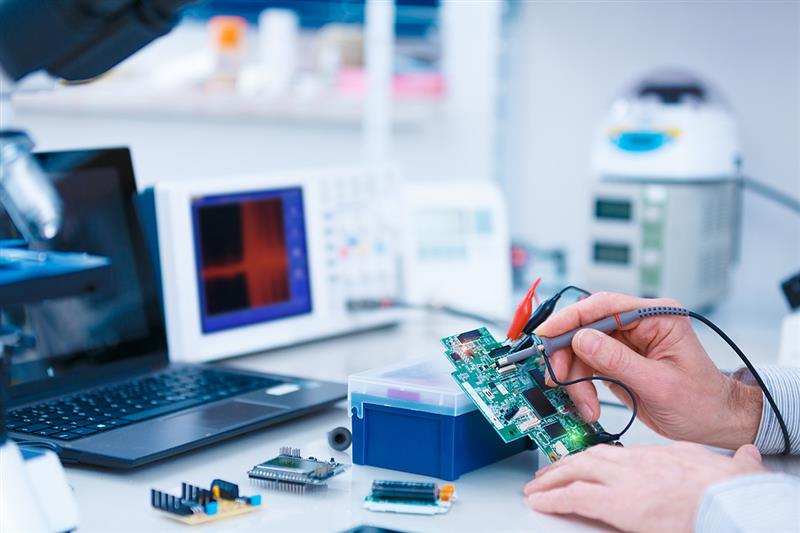

Figure 1. PCB assembly functional testing

Benefits of functional testing

PCB functional testing has several benefits which includes but not limited to:

It helps to detect and correct faults in the PCBs. There are cases where some components would be missing after assembling. Functional testing would help detect this so it’s fixed. It leaves no room for error in the final product. Without a functional testing, it's almost impossible to recognize these faults. That’s why it's super important to conduct a functional testing after assembling.

It helps to improve the PCBs quality. When a fault is detected during the functional testing, a root cause analysis is conducted to find a permanent solution to the problem. The whole process followed is documented and the document will be used as a guide for future PCB assembly. This helps to massively improve quality.

It is cost efficient. Since the functional testing stimulates the operating environment of the PCB, there’s no need for the customer to provide expensive testing equipment.

Functional testing can be used along with other PCB tests like in-circuit and flying probe testing, which in essence helps to improve in-circuit and flying probe tests results.

Areas examined during functional testing

There are signal issues that are checked and rectified during the PCB assembly functional testing. Below are some common ones:

Incorrect Voltage and current

Incorrect voltage or current is one major issue that is checked when doing PCB assembly functional testing. Without the correct supply of voltage or current to the PCB, it can’t function properly. A number of things could result in incorrect voltage supply such as an incorrect component or a missing component. Too much drop in IR in the board can also cause this voltage or current problem.

Power integrity

Some common power issues that are identified during functional testing include low frequency noise, excessive jitter and pdn ripple.

Interface test

The PCB interface is tested to detect dysfunction as a result of a Short or Open.

Functional testing plan

Functional testing plan is when you plan and factor in the test of your PCB during design. When designing, you need to determine the function of every component and how they would be tested. Also, you need to determine what it would mean for each component to function correctly. Having this though during design will help you add testing areas to your PCB schematics and layout.

Test points should be included in your PCB design once you decide on what needs to be tested. These test points are pads on the PCB where the testing equipment interacts with the PCB. Test points should be easy to probe.

Figure 2. PCB assembly functional testing point

How to do a functional testing

Functional testing involves a number of processes which includes:

Determine the function that is to be tested.

Create input data using the PCB’s function specifications.

Use the PCB's function specifications to determine expected data.

Conduct the test. The PCB's operating environment is stimulated to verify if it functions as expected. The PCB's operating environment is made of a device that communicates with the PCB. The PCB is supplied with a series of power and signals. The behavior of the PCB is monitored at various points to verify it functions correctly. The output data of the test is recorded.

Compare the output or actual data with the expected data of the PCB based on its specifications.

Functional testing fixtures

PCB test fixtures are devices that hold PCBs for testing. These fixtures help to automate PCB tests. In order words, they help to do a particular test on a PCB repeatedly and present the results. PCB test fixtures usually include a computer, control board, enclosure and a user interface. They can also include metal enclosures and 3D printed parts.

Figure 3. Test fixtures for PCB functional testing

Factors to consider when selecting a manufacturer for functional testing

To have quality and well-functioning PCB, you need a manufacturer that:

Has qualified and experienced test engineers

Has modern functional testing equipment

Collaborates with you from the design stage of the PCB to its testing. A good manufacturer will help you modify your design so as to speed up production and also make your board suitable for functional testing.

Final Thoughts

Functional testing is a super important step of the PCB manufacturing process. It helps to detect and rectify every fault in the PCB so that they function correctly. In this article, we explored various aspects of PCB assembly functional testings. We hope the information shared has helped you learn more on this subject.

If you are looking for the best PCB assembly functional testing services for your products, PCBgogo is your best option. PCBgogo has qualified and super competent test engineers who professionally test PCB with our best-in-class test equipment. This guarantees high quality PCBs that function perfectly according to your very specifications. We will work with you from the design stage and offer you super valuable guidance to come up with the best and testable designs. Contact PCBgogo today for a world class PCB assembly and functional testing services.

- Comments(4)

**

May 30.2024, 11:28:43

B****dam

May 11.2024, 07:52:23

**

Dec 18.2023, 15:19:20

C****ker

Nov 07.2023, 17:17:08