Surface-mount technology (SMT) is now used in practically all commercially made devices due to its numerous advantages in the PCB manufacturing process. SMT reduces production costs while maximizing PCB space due to its numerous advantages in the PCB manufacturing process. In this post, we'll go through the different advantages of surface mount technology. There is a good reason why surface-mount technology prevails worldwide. However, there is still a long way to go for SMT aside from the advantages that SMT already has.

What is Surface-Mount Technology

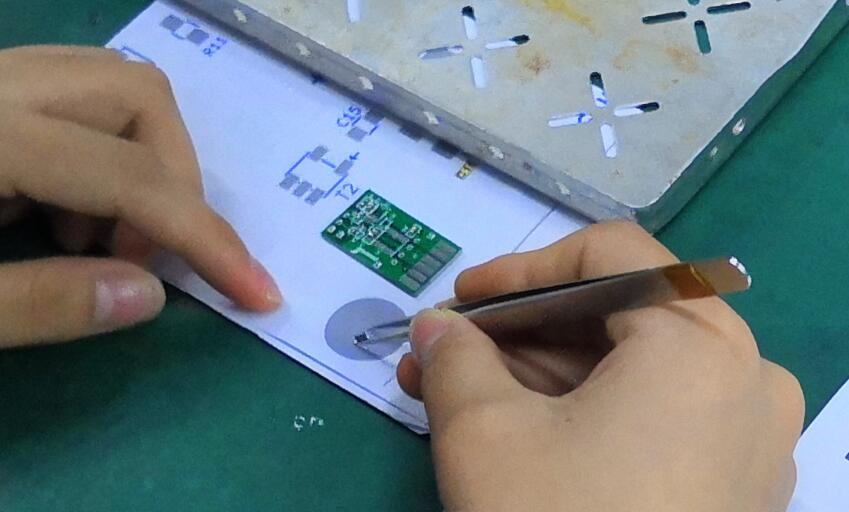

Surface-mount technology (SMT) is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD).

Image courtesy: PCBgogo

Essentially, SMT adopts the basic conception of through-hole technology (THT). However, different from THT, manufacturers don’t need to drill holes on the substrates, they only need to paste soldering on the stencil and place electrical components on the PCB.

Surface-mount technology improves the efficiency of PCB assembly and simplifies the PCB assembly process. Despite debate about the strength between surface mounting and through-hole assembly lasting for a long time, surface-mount technology does have many advantages to win, and thus, SMT is the more common choice than THT in PCB assembly.

1. Common Five Steps of SMT in PCB Assembly Factory

PCB production - fillet and fiducials will be confirmed at this step before PCB assembly.

Paste soldering flex - Use a solder-paste machine and PCB stencil to print the soldering flux neatly on the PCB.

SMD placement - With the help of automatic equipment like a pick & place machine, electronics components can be placed on the board properly.

Baking the soldering flux - Manufacturers apply reflow-oven and wave-soldering machines to consolidate surface mount devices.

Quality inspection - Besides QC inspection, manufacturers use equipment like AOI (automatic visual inspection) machine or X-ray inspection machine to check the rightness of PCB assemblies.

2. The advantages of Surface Mount Technology

Surface-mount technology settles the universal problem of lack of space in PCB assembly. Because surface-mount devices are tiny enough, Engineers could have more plans when design circuits. Meanwhile, it means more components can be placed on a PCB, which can reduce the amount of PCB for one product and save the cost of production for companies.

Surface-mounting is lead-free. Compares to THT, it is more environmental-friendly.

As surface-mount devices have shorter lead lengths than thru-hole components, the surface mount technique can reduce propagation delay and package sound.

SMT PCB can be high-density because components can be mounted on both sides of a circuit board.

SMT is more suitable than THT when companies want to shorten the product development cycle.

Surface-mount technology can improve the speed of electrical circuits. Actually, it is why most manufacturers choose SMT in PCB assembly.

The surface tension of the molten solder pulls the electrical components into alignment with the solder pads. That is to say, SMT automatically corrects any small errors that may occur in component placement.

It turns out that electrical devices soldered by surface-mount technology are more stable than through-hole technology.

Normally, surface-mount devices are cheaper than through-hole components.

Can SMT Accelerates PCB Assembly?

The most important is, SMT can greatly reduce production time since no drilling is required. Also, surface mount devices can be placed thousands per hour, while through-hole mounts less than one thousand components per hour. It achieves the desired rate of production and reduces the time for a product to come into the market. So, if you are looking to speed up your PCB production time, SMT is the answer. By using Design for Manufacturing (DFM) software tools, the need to rework and redesign complex circuits can be reduced greatly, increasing the speed and possibilities of complex electronic product designs.

All of this does not mean that SMT does not have inherent disadvantages. SMT is unreliable if it is used as the only fixation method for components that are exposed to substantial mechanical stress. Components that generate a lot of heat or are subject to high electrical loads cannot be installed by SMT. This is because the solder will melt at high temperatures. Therefore, it is likely that through-hole mounting will continue to be used where there are special mechanical, electrical, and thermal factors that make SMT ineffective.

How To Proceed Your PCB Assembly

It is not easy to assemble PCBs over ten pieces. If you aren’t a hobbyist, self-assembly won’t be a cost-effective and time-effective choice. By partnering with certain PCB manufacturers, you can make other designs or enjoy a relax while your PCB is assembled by the manufacturer.

Nowadays, turnkey PCB assembly service is a better choice for companies. The PCBs flow seamlessly from fabrication to assembly. It can greatly reduce the time of the prototyping phase and save costs for production.

If you are looking for a turnkey PCB assembly manufacturer, PCBGOGO is a trustworthy and affordable choice. Their on-time PCB assembly services, including PCB manufacturing, PCB assembly, components sourcing, functional testing has helped thousands of electronic project engineers make prototype or even mass production for years.

Sending your BOM and Gerber file to a certain turnkey PCB assembly manufacturer, you can even get the final PCB after your vacation.

Image courtesy: PCBgogo Assembly Factory

- Comments(11)

m****lam

Apr 06.2024, 20:01:36

M****Ali

Apr 04.2024, 20:15:09

M****Ali

Apr 03.2024, 19:53:18

m****lam

Apr 02.2024, 18:31:45

m****lam

Apr 01.2024, 19:54:01

C****sch

Mar 28.2024, 15:12:20

M****Ali

Mar 17.2024, 17:50:58

M****SEO

Mar 13.2024, 14:25:49

| ???? | https://www.mt-star.net/ |

M****SEO

Mar 13.2024, 14:25:24

**

Dec 21.2023, 06:57:09

I've implemented your tips, and they've made a difference. Thanks! Blessed event reveal

**

Dec 16.2023, 18:44:31