Introduction: The Growing Importance of Automotive Sensors

In today's era of advanced technology, the automobile industry is witnessing an unprecedented transformation. A pivotal part of this revolution is the evolution of automotive sensors, which have emerged as key components in modern vehicles.

These sophisticated devices collect critical data from a variety of sources, including the vehicle's engine, brakes, temperature sensors, and more, thereby enhancing vehicle performance, safety, and comfort. They enable functionalities ranging from Advanced Driver-Assistance Systems (ADAS) and Engine Control Units (ECUs), to infotainment systems, and electric vehicle battery management.

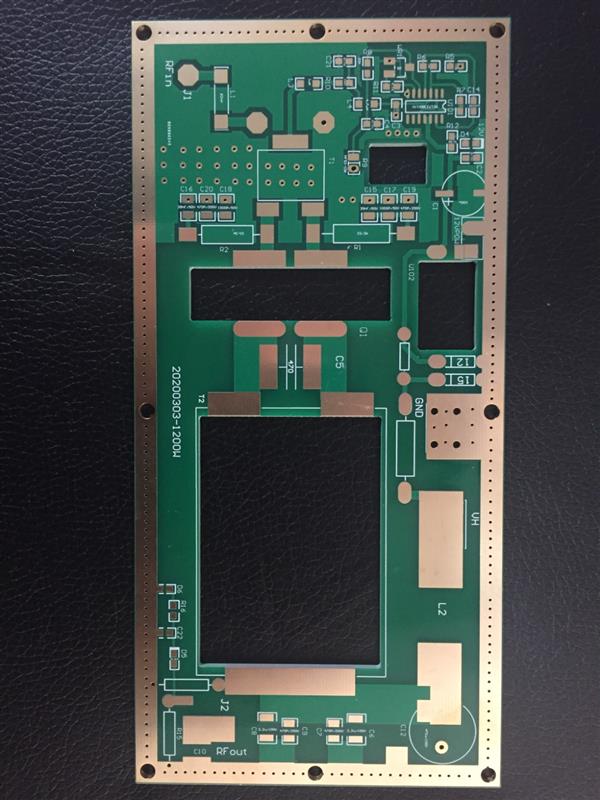

As these systems continue to grow in complexity, the Printed Circuit Boards (PCBs) that form the electronic backbone of these sensors have become increasingly intricate. This amplifies the need for meticulous and robust PCB design techniques, with via tenting being an essential part of this process.

The Role of Via Tenting in PCB Design for Automotive Sensors

Via tenting, a process that involves covering via holes on a PCB with a protective solder mask, plays an indispensable role in automotive sensor PCB design. This technique is crucial for maintaining the integrity of the circuit, preventing potential short circuits that could occur if solder or other conductive materials accidentally flow into the vias during assembly. Furthermore, via tenting protects the vias from potentially harmful environmental contaminants like dust, moisture, and automotive fluids. These contaminants can compromise the PCB's electrical performance over time, leading to malfunctions or complete system failure.

Considering that automotive applications often expose PCBs to harsh operating conditions, including high temperatures, vibrations, and chemical exposure, the protection offered by via tenting is particularly critical.

Therefore, via tentingis a key factor in enhancing the reliability and longevity of automotive sensor PCBs, ensuring that the sophisticated electronic systems they support can function accurately and efficiently under varied and sometimes extreme conditions.

Case Study: An Application of Via Tenting in Automotive Sensor PCBs

To illustrate the importance of via tenting, let's consider Engine Control Units (ECUs), which serve as the brain of a vehicle's engine. ECUs collect, process, and respond to data from numerous sensors distributed throughout the vehicle, controlling essential parameters such as fuel mixture, ignition timing, and variable valve timing. The PCBs within ECUs are densely populated with circuits and vias, making them a complex ecosystem of electronic components where via tenting plays a pivotal role.

Via tenting in these PCBs helps ensure system reliability by preventing short circuits and protecting the integrity of the vias against environmental factors. By doing so, it contributes to the long-term performance and safety of the vehicle, facilitating accurate sensor operation and response. Any failure in these systems due to unprotected vias could lead to inaccurate sensor data, potentially resulting in poor engine performance or even safety issues.

Future Trends: Via Tenting and Automotive Sensor PCB Design

As we speculate about the future, several trends could potentially shape the landscape of via tenting and automotive sensor PCB design. One of the most compelling trends could be the ongoing miniaturization of PCBs. As automotive sensors and ECUs potentially become more sophisticated, the demand for more compact and efficient designs might increase. Via tenting could play a critical role in this trend, as it might allow for high-density designs by preventing short circuits and protecting the integrity of the vias.

In addition, the development and use of advanced materials for via tenting could become more commonplace. These materials could possibly offer improved performance characteristics such as higher temperature resistance, better adhesion, and greater protection against environmental factors. This could potentially lead to longer-lasting and more reliable automotive sensor PCBs.

Furthermore, as the complexity of automotive sensor systems potentially increases, there might be a growing need for advanced PCB design tools. Automation and AI could be harnessed to optimize the via tenting process, potentially ensuring optimal placement and size of vias to maximize signal integrity and performance.

Conclusion: Via Tenting as a Key Technique for Automotive Sensor PCB Designers

In conclusion, via tenting is currently a widely used technique in the design of automotive sensor PCBs, significantly contributing to the reliability, performance, and longevity of these vital systems. As the automotive industry potentially continues to evolve with emerging technologies, the importance of robust PCB design techniques such as via tenting cannot be understated.

The future of automotive sensor PCB design could potentially be shaped by ongoing trends such as miniaturization, the possible development of advanced materials, and the speculated increased use of automation and AI in PCB design. These trends could further amplify the significance of via tenting in maintaining circuit integrity and preventing short circuits, possibly reinforcing its role as a key tool for PCB designers in the automotive industry.

Through this exploration, we hope to have shed light on the critical role of via tenting in automotive sensor PCB design. As we speculate about a future driven by increasingly complex and sophisticated automotive technologies, understanding and employing robust design techniques like via tenting might be essential for designing reliable, high-performance automotive sensor systems.

- Comments(18)

j****ill

Mar 29.2024, 00:48:50

peacocktv.com/tv is one of the streaming services that many people around the world are interested in. NBC Widespread possesses peacocktv.com/tv/samsung, the administrations offered incorporate many movies and Network programs open for streaming. A couple of the famous and most notable shows on the pop scene incorporate Works of art like the workplace and the cheers as well as current shows like Rule of peace and law and This Is Us.

M****owe

Mar 07.2024, 21:01:33

[url=https://google.com]google[/url]

[google](https://google.com)

[[https://google.com|google]]

[google->https://google.com]

M****owe

Mar 07.2024, 18:13:33

L****Ang

Jan 25.2024, 04:34:24

L****Ang

Jan 25.2024, 04:33:41

Lecia Ang

<a href="https://www.northshorelandscaping.com.au/services/retaining-walls/">Retaining Walls North Shore</a>

A****ays

Jan 11.2024, 10:42:28

((https://google.com/ google))

[https://google.com/ google]

[[https://google.com/ google]]

[L=google]https://google.com/[/L]

"google":https://google.com/

[google](https://google.com/)

A****ays

Jan 11.2024, 10:41:29

**

Jan 05.2024, 15:16:16

K****ane

Dec 27.2023, 16:35:36

p****nda

Dec 22.2023, 18:15:57

P****ton

Dec 19.2023, 12:20:48

P****ton

Dec 18.2023, 16:36:34

F****ela

Dec 05.2023, 10:27:00

**

Dec 01.2023, 12:59:31

C****nna

Nov 29.2023, 15:49:42

**

Nov 14.2023, 11:32:49

M****ali

Oct 30.2023, 09:58:10

To give you an idea, I take a magnesium supplement in the evening, and I consume coffee in the morning and sometimes at lunch.

<a href="https://run3online.io">run 3</a>

N****eng

Sep 07.2023, 15:09:13

2024年世界电池与储能产业博览会(WBE)

2024世界氢能产业博览会

时间:8年10月2024-<>日

地点:中国进出口商品交易会展馆A区1楼、2楼

地址:中国广州市越江中路380号

WBE 2023 回顾

由广州诚信展览有限公司主办的第八届世界电池与储能产业博览会(WBE 8)于2023月8日至10日在广州中国进出口商品交易会展馆A区成功举办。

展会面积超过100,000平方米,共占据了8个展厅,设置了3957个展位,几乎是去年的两倍。1205家参展公司参加了展会。 电池芯、电池组和储能解决方案参展商数量达476家。

熙熙攘攘的三天共接待了137,500人次,其中包括来自美国,德国,韩国,法国,日本,英国,瑞典,比利时,捷克共和国,新加坡,马来西亚,印度尼西亚,印度,泰国,巴西,南非等50多个国家和地区的海外买家。

中国电池产业(广州)峰会、中国储能产业生态大会、世界氢能与燃料电池产业大会以及首届为期两天的工厂参观计划构成了WBE 2023的最大亮点。

WBE 2024预览

WBE将力争在2024年再次打破自己的展会规模记录,预计共占据13个展厅,总面积达165,000平方米,汇集约2000+优质参展商。

让海外买家亲眼深入了解中国领先的电池和电池设备制造商,强烈推荐的为期两天的工厂参观计划将在2024年隆重回归。我们期待更多海外观众的积极参与!

WBE 2024的现场活动和活动

2024年中国电池产业(广州)峰会

2024年中国储能产业生态大会

2024年世界氢能产业大会

2024年两日工厂参观计划

展商简介

1)各种电池,电池组和电芯,BMS

2) 储能产品

3) 电池充电和交换产品

4) 各种电池的原材料和组件

5)电池制造设备、检测设备及仪器

6)电池回收和国际物流

7)氢能及氢能应用领域

WBE 2024 的展位预订现已开放。请随时与我们联系。

联系我们

广州诚信展览有限公司

联系人:娜塔莉亚

手机: +86 18565156106

电子邮件: Nataliawbe@163.com