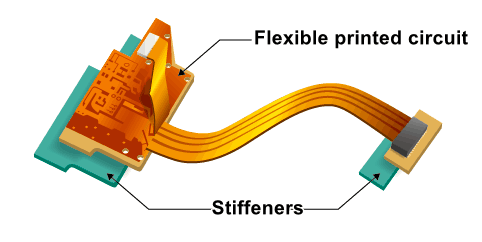

Flex PCB is a patterned arrangement of printed circuits and components that makes use of flexible base material with or without a flexible cover layer. It can be bent, wound, folded freely, and withstand millions of dynamic bending without damaging the circuit. Flex PCBs are characterized by being soft, thin, and bendable. But they will be difficult to handle when certain thickness and hardness are required for component mounting and connection. Stiffeners are particularly used to reinforce a specific area of flexible circuitry.

Benefits of Stiffener

Stiffeners are attached to flexible boards for a variety of purposes. They are not a part of electricity circuitry but only provide mechanical support for the Flex PCBs. There are mainly two purposes as follows.

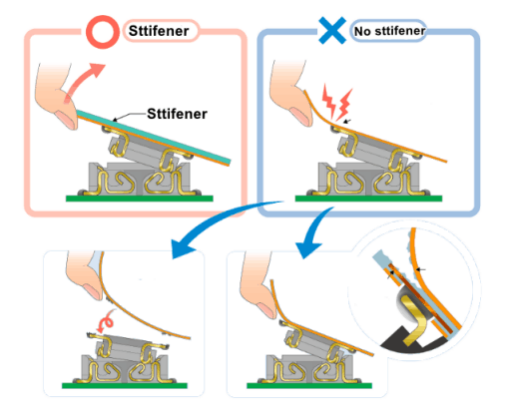

1. Improve the harness of the connection terminals

When the connectors are placed on the flex PCBs, the pads are easy to fall off after multiple insertions. The stiffener provides a certain degree of hardness and would help reduce the stress of the pads.

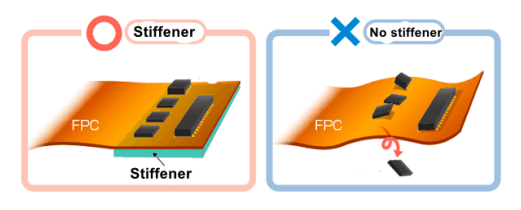

2. Facilitate the PCB assembly process

Flex PCB will bend in the reflow oven, which might lead to failures in the assembly process. The applications of stiffener offer a stable and flat surface for mounting the components. It also protects the solder joints by preventing the Flex PCB from twisting in the components area.

Materials of stiffener

There are no technical restrictions on the choice of stiffener material as long as it satisfies the intended use. In reality, the material used as the base layer for rigid boards and flexible boards are the popular products for stiffeners, which include FR-4 and Polyimide. In addition, metal sheets such as aluminum and stainless steel with properties that cannot be obtained with ordinary printed circuit board materials, are also used in specific applications.

FR-4

FR-4 Stiffener consists of glass fiber cloth and epoxy resin glue, which is the same as the FR-4 material used in rigid PCBs. As a kind of flame-resistant material, FR-4 has excellent electrical properties, mechanical properties, dimensional stability, impact resistance, and moisture resistance over other resin glass fiber cloth substrates. It is mainly used on the back of the FPC mounting area to strengthen the hardness and protect the components from being damaged when the Flex PCB is twisting and stretching.

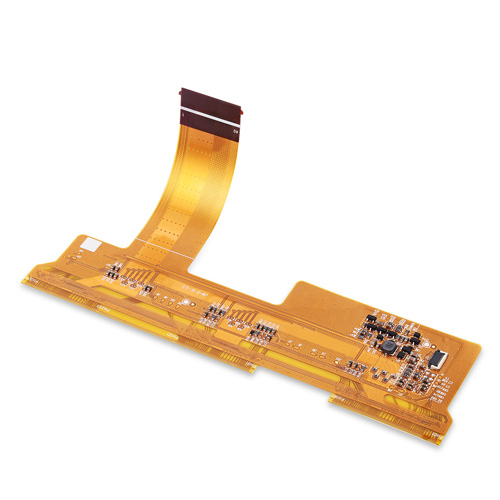

Flex PCB with FR-4 stiffener on both terminals

Polyimide (PI)

As a special engineering material, PI has been widely used in aviation, aerospace, microelectronics, nano, liquid crystal, separation membrane, laser, and other fields. It has flame retardancy, high-temperature resistance, and low-temperature resistance at the same time, and its long-term use temperature can be -200 ℃ ~ 426 ℃. In the production of Flex PCB, PI is mainly used as a protective film and Stiffener. The PI protective film serves as insulation for the circuit while stiffener is commonly applied under the gold finger of the Flex PCB to ensure it meets specific ZIF connector specifications. The thickness of the PI Stiffener mainly depends on the circuit design and the working environment.

Flex PCB with PI stiffener( Brown part)

Metal sheets

Aluminum and stainless steel sheets, which are chemically stable and have excellent corrosion resistance, are often used as the material for Flex PCB stiffener. In some cases, special alloys may be employed to offer additional springiness. These metal sheets have the following characteristics that are different from the normal stiffener material.

Conductivity: Can be used as a ground circuit.

Moldability: Can be used for forming 3D components, fixing with screws, and as a part of the housing.

Thermal conductivity: Can be used as a heat sink.

Heat resistance: Stable and does not deteriorate heat even at high temperatures.

Flex PCB with aluminum stiffener is always used in powertrain modules of automobiles that focus on thermal conductivity. In this case, almost the entire surface of the flexible board is covered with an aluminum stiffener acting as a heat sink to remove heat. It is also a carrier for mounting parts and becomes a part of the housing after 3D molding. Stainless steel usually refers to 303 stainless steel that is used where easy cutting and high surface finish are required. It is made by potion etching, which meets the needs for high-precision component assembly. But the process is quite complicated so its cost is significantly higher than polyimide and FR-4 stiffeners.

Conclusion

The popularity of 5G and information products calls for advancement and innovations of electronic devices. As electronic products come in smaller and lighter sizes, the need for Flex PCBs continues to grow. Characterized by their softness, Flex PCBs require a certain degree of hardness and thickness in the component mounting area and terminals, which is achieved by Stiffeners. Stiffeners have their own characteristics depending on the material used. As a leading Flex & Rigid-Flex PCB manufacturer in the industry for over 10 years, PCBGOGO provides PI, FR-4, Aluminum, Steel, and Coppe stiffener as per requirement. The stiffener thickness is available in 0.1~0.5mm according to your specific needs. Contact them today to get your Flex PCBs manufactured.

- Comments(27)

H****hon

May 30.2024, 18:23:11

H****hon

May 30.2024, 12:22:02

H****hon

May 29.2024, 19:55:10

H****hon

May 29.2024, 18:13:20

H****hon

May 29.2024, 17:41:07

H****hon

May 29.2024, 17:40:49

|

Really nice style and design and excellent content , nothing at all else we need. floor sanding Sydney |

|

j****mes

May 29.2024, 14:47:52

H****hon

May 29.2024, 13:16:06

H****hon

May 28.2024, 13:31:49

H****hon

May 28.2024, 12:30:45

j****mes

May 27.2024, 19:22:19

H****hon

May 27.2024, 17:42:16

H****hon

May 26.2024, 20:16:03

H****hon

May 26.2024, 15:13:55

H****hon

May 26.2024, 13:38:45

**

May 25.2024, 13:19:37

**

May 22.2024, 15:48:04

**

May 19.2024, 15:51:39

m****lam

Apr 06.2024, 19:00:36

s****sss

Apr 04.2024, 19:47:15

M****Ali

Apr 03.2024, 17:47:16

s****sss

Mar 17.2024, 18:46:09

s****sss

Mar 13.2024, 14:26:50

**

Mar 11.2024, 15:41:40

J****nes

Feb 23.2024, 16:08:08